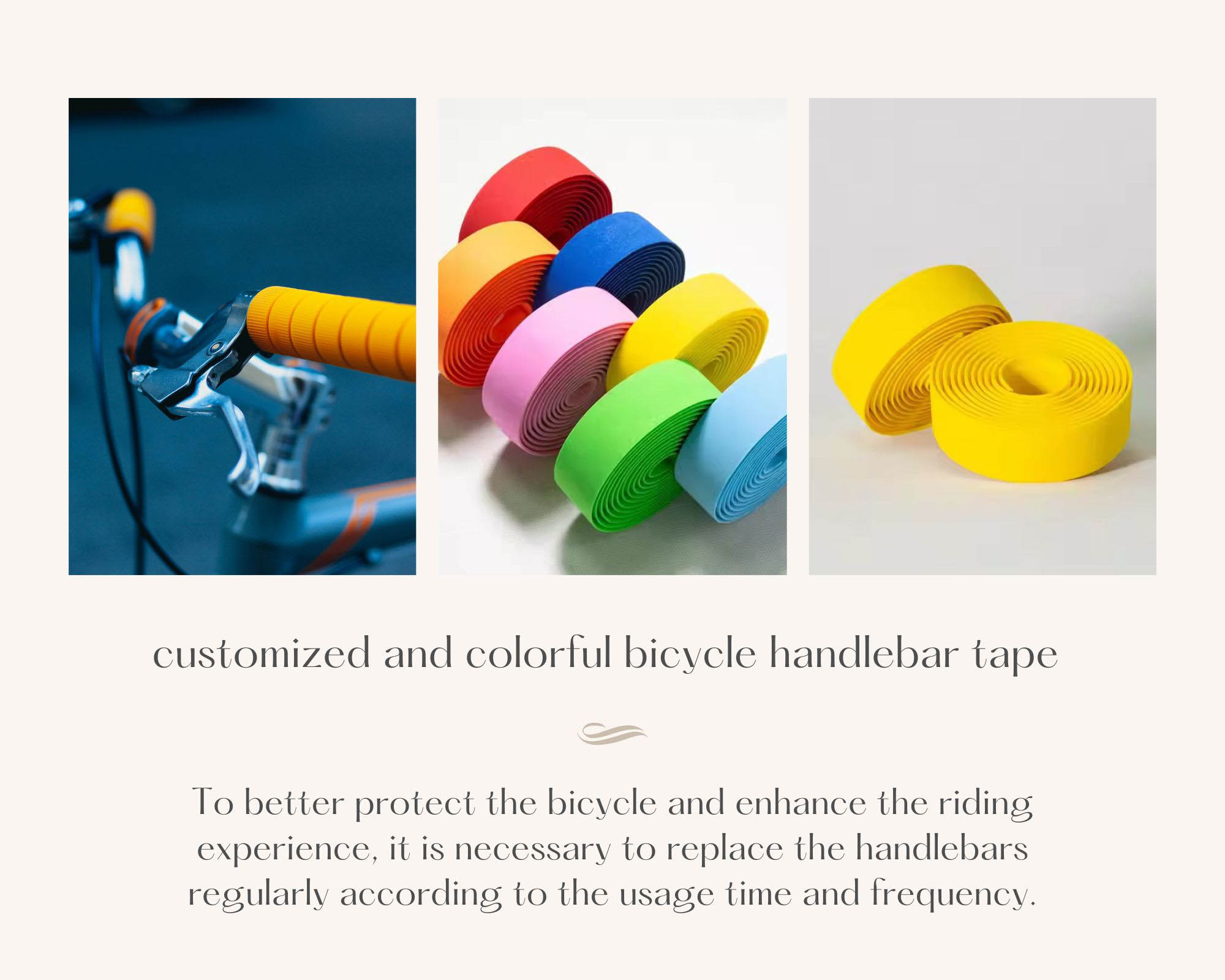

In tennis, overgrips play a crucial role in the hitting experience. The right size of a tennis overgrip not only enhances the comfort of grip but also improves the stability and control of hitting. So, how exactly should one choose the size of a tennis overgrip? Taking the racket overgrips produced by our KEET company as an example, we will analyze and provide answers from three aspects: the length, width, and thickness of the overgrip.

First of all, overgrip length, determining the number of wraps and grip fullness.

The length of a tennis overgrip typically ranges from 1100 to 1150 mm. A longer overgrip can be wrapped more times, making the handle fuller, while a shorter one results in fewer wraps and a relatively thinner handle. A longer overgrip offers a fuller grip, allowing the hand to make full contact with the handle and increasing the stability of the grip. For players with larger hands or those who prefer a thick grip, a long overgrip can better fill the gap between the palm and the handle, reducing shaking during swings and making hits more precise. A shorter overgrip, after being wrapped, results in a thinner handle, which is suitable for players with smaller hands or those who pursue a flexible grip. A thin handle allows fingers to move more freely, facilitating various hitting actions.

Secondly, overgrip width, affecting grip comfort.

The width of a tennis overgrip generally falls between 25 - 27 mm. A wider overgrip can cover a larger area of the handle, providing more even grip pressure, while a narrower one is more flexible, facilitating finger bending and stretching. A wider overgrip can distribute the pressure exerted by the hand on the handle, reducing fatigue caused by long-term gripping. For players with strong hand strength or those who often engage in long-duration matches, a wide overgrip offers better comfort and support. A narrower overgrip allows fingers to move more freely, enabling delicate hitting actions. For players who prioritize feel and control, a narrow overgrip can better transmit the force from the fingers, making hits more precise.

Finally, overgrip thickness, balancing cushioning and grip feedback.

The thickness of a tennis overgrip usually ranges from 0.6 - 0.8 mm. A thicker overgrip can provide better cushioning, reducing the vibration felt by the hand, while a thinner one is more sensitive and can better transmit the feel during hitting. A thicker overgrip can effectively absorb the vibration generated during hitting, alleviating hand fatigue and the risk of injury. For players with wrist or arm injuries, a thick overgrip offers better protection. A thinner overgrip enables players to more clearly sense the vibration and feedback during hitting, facilitating timely adjustment of hitting actions. For players who pursue precision and control, a thin overgrip provides better feel and maneuverability.

Choosing the size of a tennis overgrip requires a comprehensive consideration of its length, width, and thickness. Enterprise customers should also take into account various factors such as hand size, playing style, competition requirements, and court conditions based on consumer and market demands. They should select a variety of overgrip sizes suitable for the target consumer group, allowing consumers to make choices and thus gaining more consumer support.