In many ball sports, grip tape serves as the crucial connecting layer between the racket and the palm, with its condition directly influencing grip stability, power accuracy, and athletic comfort. However, many players are puzzled about the frequency of grip tape replacement: How often is it appropriate to replace grip tape? This article will comprehensively consider factors such as exercise intensity, perspiration levels, and grip tape material to provide customers with scientific and reasonable recommendations on grip tape replacement frequency.

I. Exercise Intensity: The core factor determining grip tape wear rate.

Exercise intensity is the primary factor influencing grip tape replacement frequency. High-intensity exercise entails more frequent gripping, exertion, and friction, which accelerate grip tape wear and performance degradation.

1. Professional players and high-frequency trainers.

For professional players or individuals engaging in high-intensity training daily, grip tape requires relatively frequent replacement. During intense matches and training sessions, the number of hand-grip tape frictions increases significantly, and perspiration secretion becomes more vigorous, leading to a rapid decline in the grip tape's anti-slip and sweat-absorbing properties. It is recommended to replace grip tape 1 - 2 times a week. If the training volume is extremely high, such as training for more than 4 hours daily, daily replacement may even be considered, especially before important matches, to ensure the grip tape is in optimal condition.

2. Amateur enthusiasts and low-frequency trainers.

For amateur enthusiasts or players who train less frequently and at lower intensities each week, grip tape replacement frequency can be relatively lower. Replacement every 2 - 3 weeks is advisable. However, if each training session lasts more than 2 hours and involves significant hand perspiration, the replacement frequency should be appropriately increased to once every 1 - 2 weeks.

II. Grip Tape Material: An intrinsic factor determining lifespan.

Different grip tape materials possess varying performance characteristics and lifespans. Therefore, when selecting grip tape, in addition to considering personal preferences and usage habits, replacement frequency should be reasonably determined based on material characteristics.

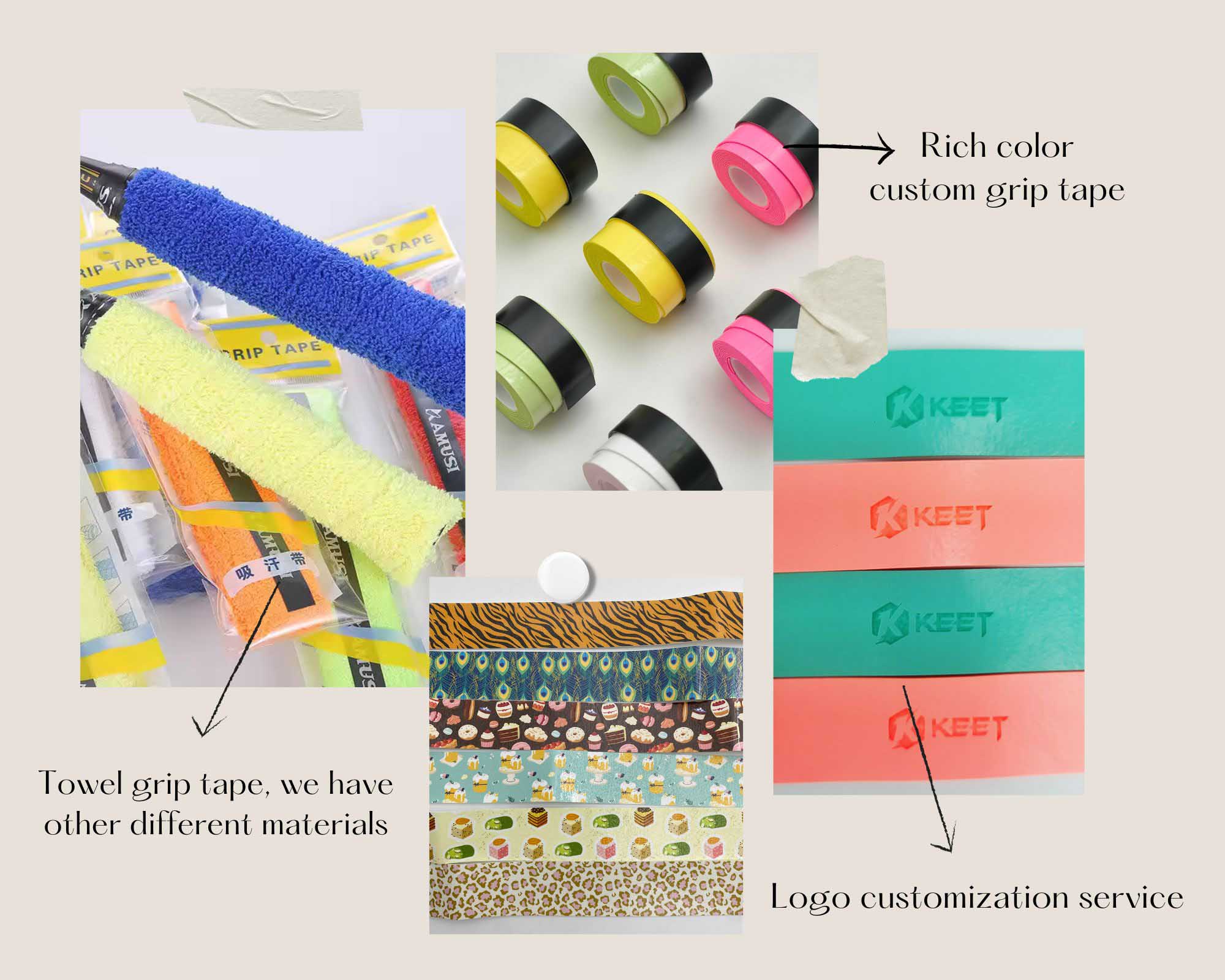

1. Towel grip tape.

Towel grip tape is favored by many players for its soft texture and excellent sweat-absorbing properties. However, it is also more prone to accumulating sweat and bacteria, resulting in a relatively short lifespan. After high-intensity exercise, towel grip tape tends to become heavily saturated with sweat, so it is recommended to replace it after each high-intensity exercise session. If exercise intensity is low and perspiration is minimal, towel grip tape can be replaced every 1 - 2 weeks.

2. PU grip tape.

PU grip tape offers good anti-slip performance and durability and is one of the most common grip tape materials on the market. During high-intensity exercise, it can be replaced every 2 - 3 weeks. For low-intensity exercise, replacement every 1 - 2 months is sufficient. However, if wear, delamination, or loss of anti-slip performance is observed on the PU grip tape surface, it should be replaced promptly.

III. Comprehensive recommendations and precautions.

1. Regularly inspect grip tape condition.

Regardless of exercise intensity, perspiration level, or grip tape material, grip tape condition should be regularly inspected. If wear, delamination, hardening, loss of elasticity, or a decline in anti-slip performance is observed on the grip tape surface, it should be replaced promptly.

2. Maintain hand and racket cleanliness.

The cleanliness of hands and rackets also affects grip tape lifespan. Before and after exercise, use a clean towel to wipe hands and rackets to prevent sweat and stains from accumulating on the grip tape.

3. Carry multiple grip tapes.

To prepare for unexpected situations or high-intensity exercise demands, it is advisable to carry several grip tapes. This allows for timely replacement when grip tape performance declines, ensuring exercise continuity and comfort.

There is no fixed standard for grip tape replacement frequency. Instead, it should be comprehensively considered based on factors such as exercise intensity, perspiration level, and grip tape material. By scientifically and reasonably determining grip tape replacement frequency, we can consistently maintain a good grip and usage experience, enjoying the pleasure of badminton. We hope the recommendations in this article will be helpful to our customers, enabling them to make a purchase with a better understanding of grip tape.